Nickel Plating Procedure.

1. Mechanical Cleaning Pretreatment: The pipe, fitting, welded assembly are sand blasted from inside to remove rust, scales, paint etc. adhering to the surface.

2. Chemical Cleaning: The Sandblasted components are taken for chemical cleaning to ensure the surface is free of oil, grease and any other substances adhering to the surface to be plated. The chemical cleaning takes place in following steps:

a) Soak Cleaning: The components are dipped in SK-40/CK1/F-50 ( Degreasing Alkaline chemical ) chemical solution maintained at 60-70 ºC for 10-15 mins. The concentration of solution is 25-30 gm/litre of water.

b) The components are subsequently rinsed in water at room temperature for 12-15 mins, to remove the residual chemical.

c) The components are Acid pickled in H2SO4 (10-25 % v/v) solution kept at room temperature for 10-15 mins.

d) The components are again rinsed in water for about 10 mins to remove the residual acid.

e) The components inside is recirculated with Sulphamic Acid solution for 10-15 mins at room temperature. The concentration of Sulphamic acid is initially kept at 30-40 gms/litre.

f) D.M. water rinse.

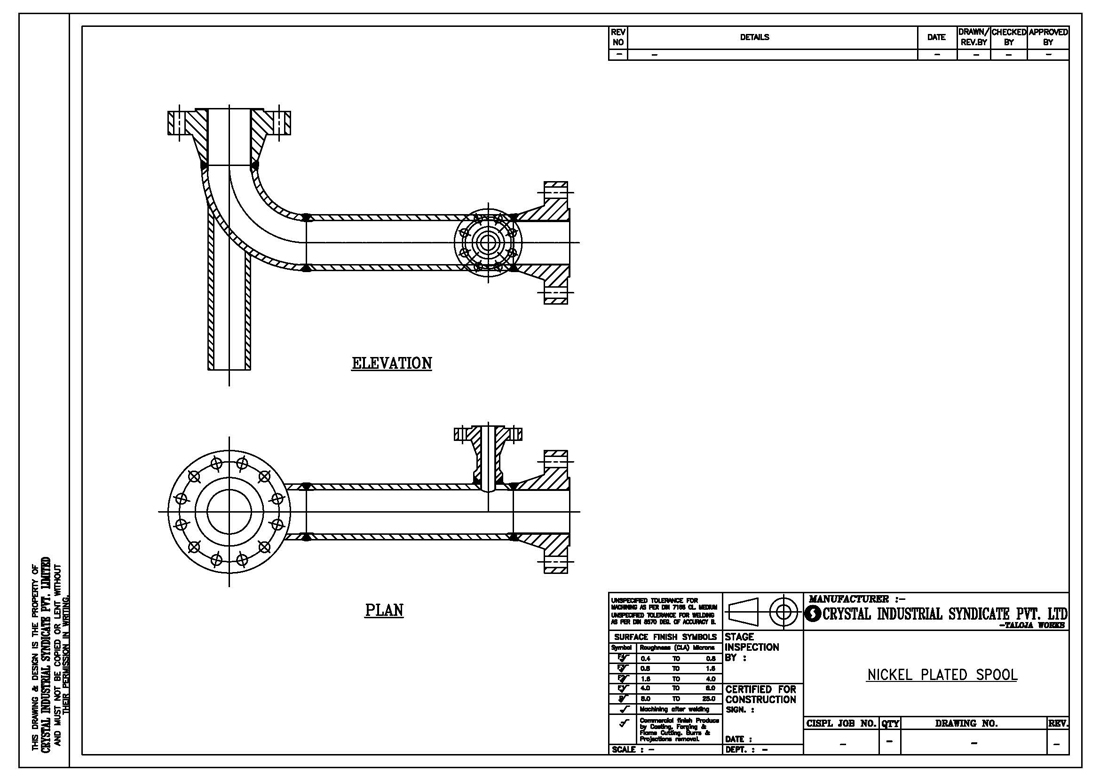

3. Nickle Plating: The component to be plated is taken for plating process immediately after the cleaning process; Nickel Anodes are placed in Titanium baskets placed at the centre of the component & Nickel Sulphamate solution is recirculated inside the component. This solution consists of Nickel Chloride & Boric Acid. The composition of solution is Nickel metal- 70-75 gms/litre; Nickel Chloride 4-6 gms/litre & Boric Acid- 30-35 gms/litre. The recirculation is continued for 1500 mins at current Density of 20A/Sq. feet is maintained throughout the duration. This will ensure uniform deposition of 400 microns ( minimum ) of nickel in the inside surface of pipes, fittings etc.

4. Post Cleaning: The assembly is thoroughly cleaned with water, 2 times each for a duration of 2-3 mins to remove the chemicals and dried. The assembly is then stress relived at 190-200 ºC for 120 mins.

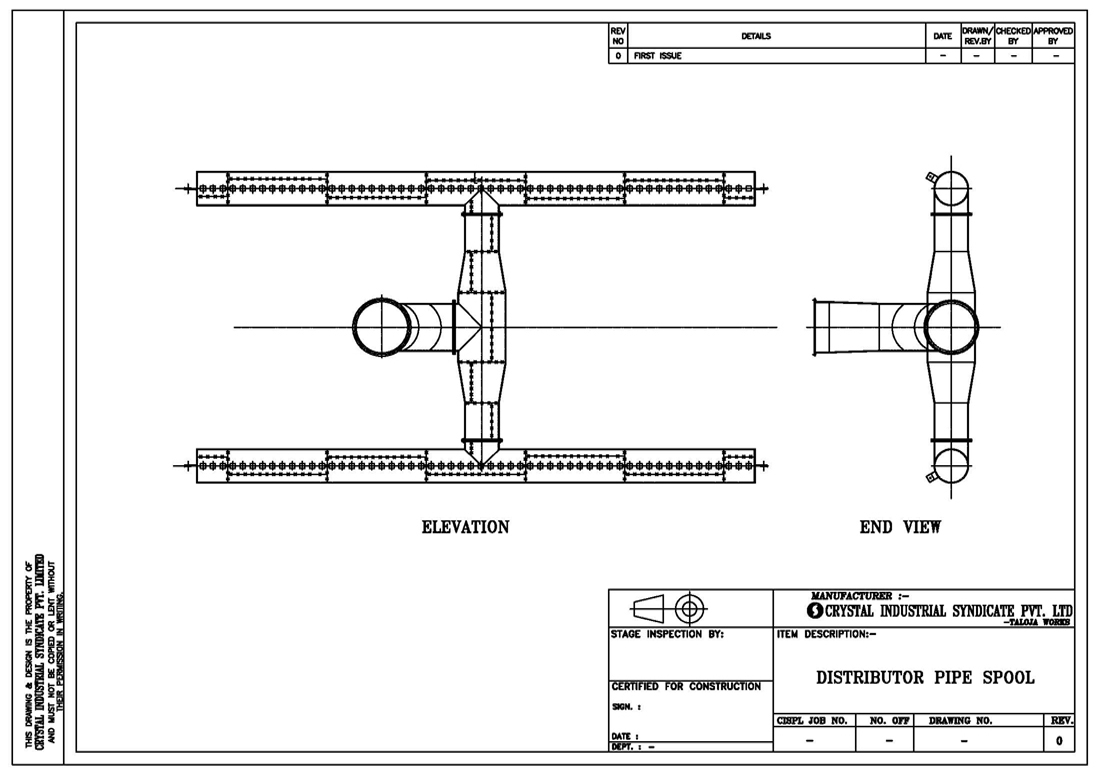

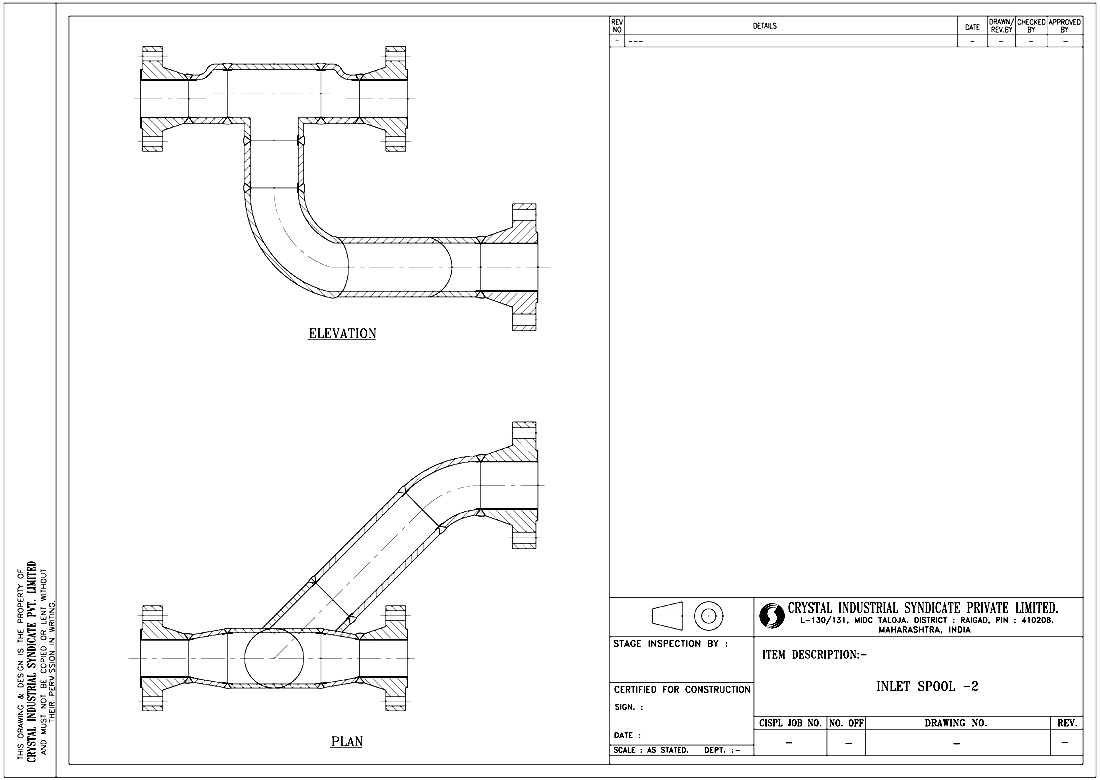

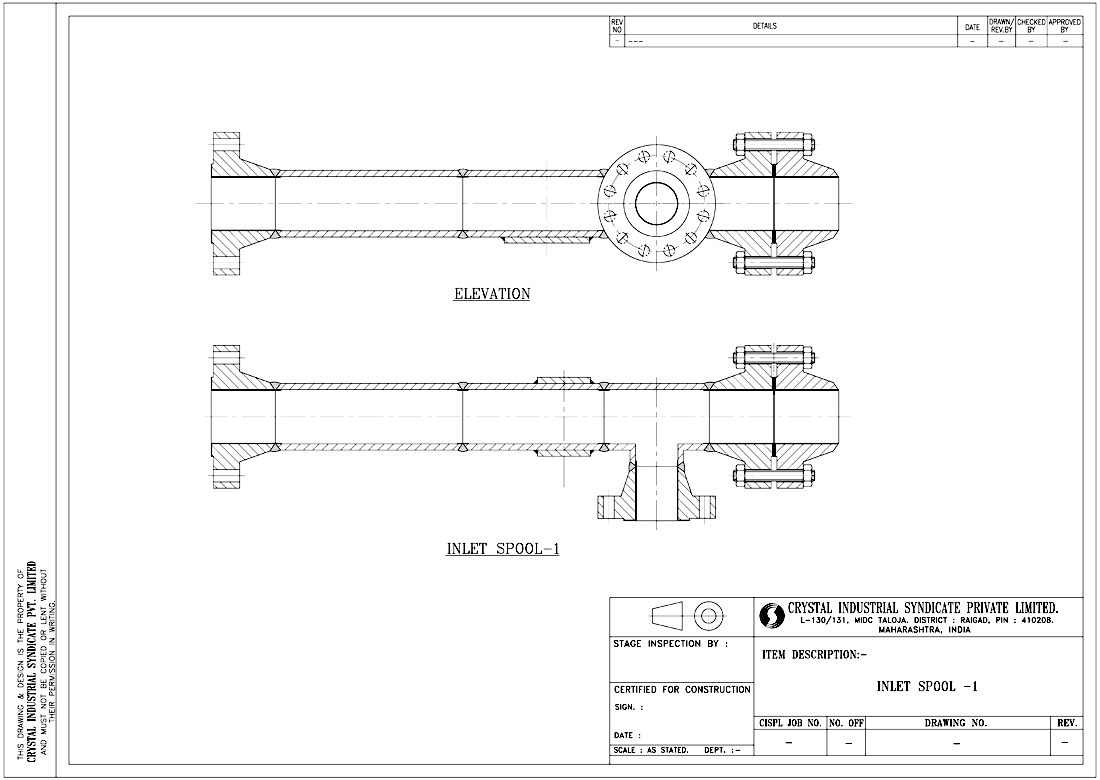

Pipe Spool Fabrication in Exotic metals and low Alloy Steels

Crystal specializes in fabrication and supply of prefabricated spools in exotic metals like Inconel, Hastelloy and other low alloy steels like P11, P22 Etc. Crystals Degreed and Trained Engineers have executed many spool fabrication contracts for new projects and shut down project for the easy installation at site. Combination of experienced design Engineers and a full pledged manufacturing facility has given the edge to complete the spool fabrication process a per customer schedule with full compliance to the customer specifications and quality requirements. In house welding engineering team, production engineering team has served many esteemed customers in getting the best value in terms of complete technical compliance and productivity. The piping spools are subjected to customer specified quality control test like Radiography, Ultrasonic test, P.T. Examination, Hydro static and Pneumatic tests.