Condenser Scrubber All Products

Condenser Scrubbers are designed to condense, absorb, cool and scrub large volume of gases. Four different scrubber designs allow a choice of the one best suited to the application. They are available in size ranging from 12” (300 mm) to 96” (2400 mm) with capacities up to 25,000 cubic feet per minute CFM (42,500 m3/hr).

OPERATION

If a draft is required to move the gas through the system, a blower can be installed at the discharge. A Type 910 Scrubber may also be used in series with these units to provide a draft and increase scrubbing efficiency.

CONSTRUCTION

Condenser scrubbers are available in any metal capable of fabrication. The most common construction materials include steel, stainless steel, Hastelloy Alloy 20, Inconel, Titanium, and Monel. They are also available in fiberglass reinforced plastic, fluoropolymer, thermoplastic, or rubber lined steel construction.

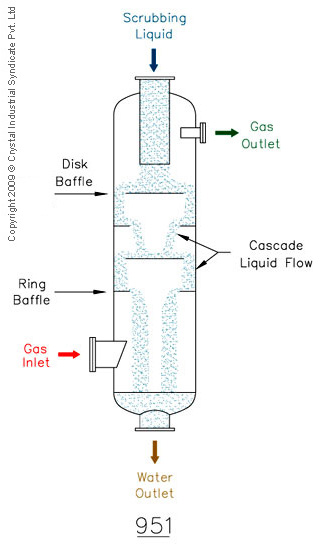

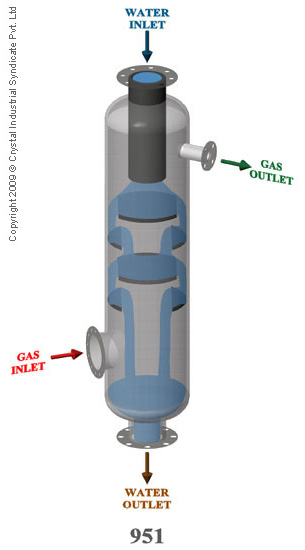

TYPE 951 CASCADE SCRUBBER

The Type 951 Cascade Condenser Scrubber is a counter-current flow unit which is designed to condense, absorb and cool large volumes of gases. The low-pressure liquid is supplied to a series of discs and rings that form curtains of liquid which cascade down through the rising flow of gases. Liquid and condensables are removed and discharged or recirculated. Cooled gases exit through the outlet to atmosphere or process piping. Gas/liquid contact time can be extended by increasing the height of the scrubber and adding more discs and ring. This unit has special in heavy particulate removal applications. The Type 951 can be modified to permit the use of a mist-eliminator.

TYPE 952 MULTI-NOZZLE CO-CURRENT SCRUBBBER

The Type 952 Scrubber is a co-current flow design incorporating a ring of spray nozzles. This scrubber is suitable for quenching, absorbing and condensing highly soluble gases. In this design, liquid is supplied under pressure to a water box holding the ring of nozzles. These nozzles cover the entire gas flow path with a liquid spray. The Type 952 Scrubber can be conveniently installed in series with a counter-current scrubber for additional scrubber for additional scrubbing.

TYPE 954 MULTI-NOZZLE COUNTER-CURRENT SCRUBBER

Similar in design to the Type 952 scrubber, the Type 954 Scrubber is a counter-current flow unit designed to handle steam or other condensable gases. The counter-current flow promotes rigorous mixing of gas and liquid for maximum absorption.

TYPE 958 SINGLE NOZZLE SCRUBBER

The Type 958 Single Nozzle Spray Condenser Scrubber is a counter-current flow design incorporating a single large spray nozzle. This scrubber is used for condensing, absorbing, and cooling gases. Liquid, supplied under pressure to the nozzle, is broken into a fine solid conical spray which contacts the rising gases from the gas inlet. The water and condensable gases drop out of the gas stream to the bottom of the scrubber where they are drained from the scrubber. Non-condensable gases are cooled and scrubbed as they pass through the liquid spray. Saturated non-condensable gases exit through the gas outlet. The counter-current flow design maximizes liquid-gas contact for increased efficiency. By moving the spray nozzle to the side of the scrubber, a mist-eliminator can be placed before the gas outlet to reduce moisture carryover.

In technical collaboration with Severn Trent Services

High pressure access fittings

High pressure access fittings

Fixed & Retractable Injection Quills

Fixed & Retractable Injection Quills

Corrosion coupons

Corrosion coupons

Required accessories

Required accessories