How the Ejector-Venturi Scrubber Works

Contaminated gas is drawn into the Ejector-Venturi Scrubber by means of the ejector action of a high velocity liquid spray directed into a venturi throat. This high velocity spray is generated by the motive liquid pressure. The spray impinges on the venturi throat to induce the draft-producing action. The venturi throat is a high turbulence zone where maximum gas-liquid contact and mixing occur. It is this intimate contact which produces effective scrubbing. The scrubbed gases then leave the throat area with the contaminants impacted or absorbed into the scrubbing liquid. The diverging section is designed to regain as much as possible of the system energy and to reagglomerate the scrubbing liquid droplets for ease of entrained.

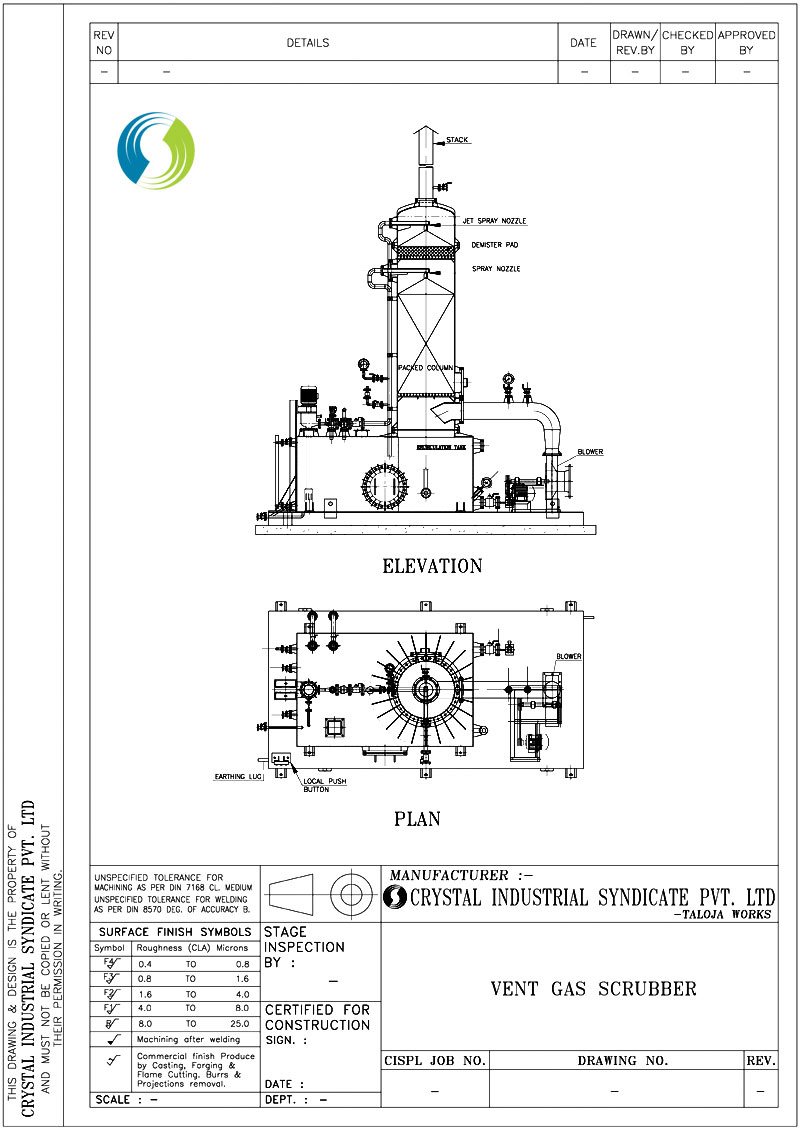

PACKED TOWER SCRUBBERS

Type 955 Packed Tower Scrubber is a low energy, contact bed type of wet scrubber for gas absorption, for gas cooling, and for stripping of the contaminants, from process liquids. The units are specifically engineered to give the highest efficiency with the lowest power consumption without sacrificing performance reliability. Packed Tower Scrubbers are available in standard designs from 6” (150 mm) to 144” (3600 mm) diameter and with capacities to 50,000 cubic feet per minute (CFM) (85,000 m3/hr).

PRINCIPLES OF OPERATION

Contaminated gas enters bottom side of the scrubber and flows upward through the packed bed. The scrubbing liquid is introduced through a distributor at the top of the packed section and trickles downward through the packing, removing the contaminants from the gas through the interaction of the gas, liquid, and packing media. The scrubbing liquid falls to the recirculation sump at the bottom of the unit. The cleaned gas proceeds upward through a mist eliminator to the gas outlet.

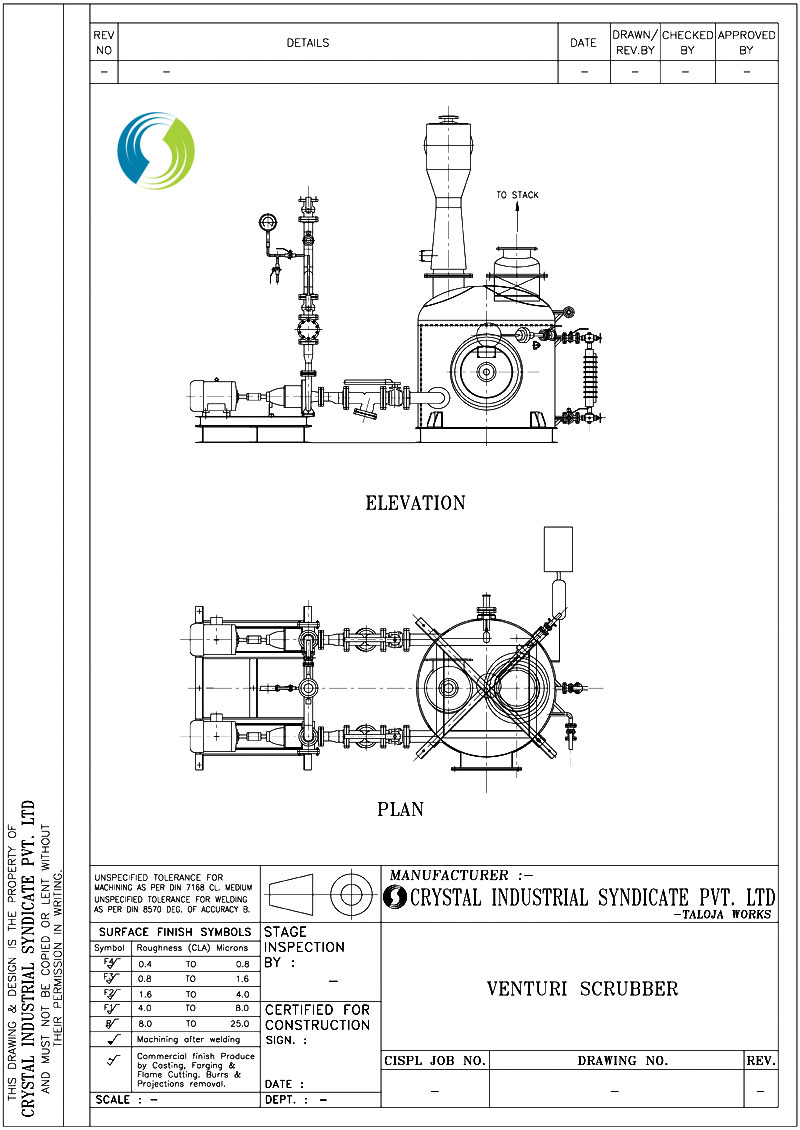

HIGH ENERGY VENTURI SCRUBBERS

PRINCIPLES OF OPERATION

High Energy Venturi Scrubbers are designed for the removal of sub-micron fumes, mists, and particulates. The gas is accelerated into the throat of the venturi where the high velocity gas stream shatters the scrubbing liquid into fine droplets which mix with and impinge on the fine fumes, mists, and particulates to effect the required removal efficiency.

The scrubber are vertical flow, wet approach type where the scrubbing liquid is introduced at the top of the converging section of the venturi. The wet approach feature allows the scrubber to be used in hygroscopic or highly abrasive applications. These units are capable of scrubbing with recirculated slurries having a solids content as high as 30%.

The throat area of the venturi can be selected to operate at pressure drops between 6” (150 mm) and 120” (3000 mm) column of water.