High pressure access fittings consist of five basic components:

- Cover

- Access Fitting Body

- Plug Assembly

- Service Valve

- Retrieval Tool

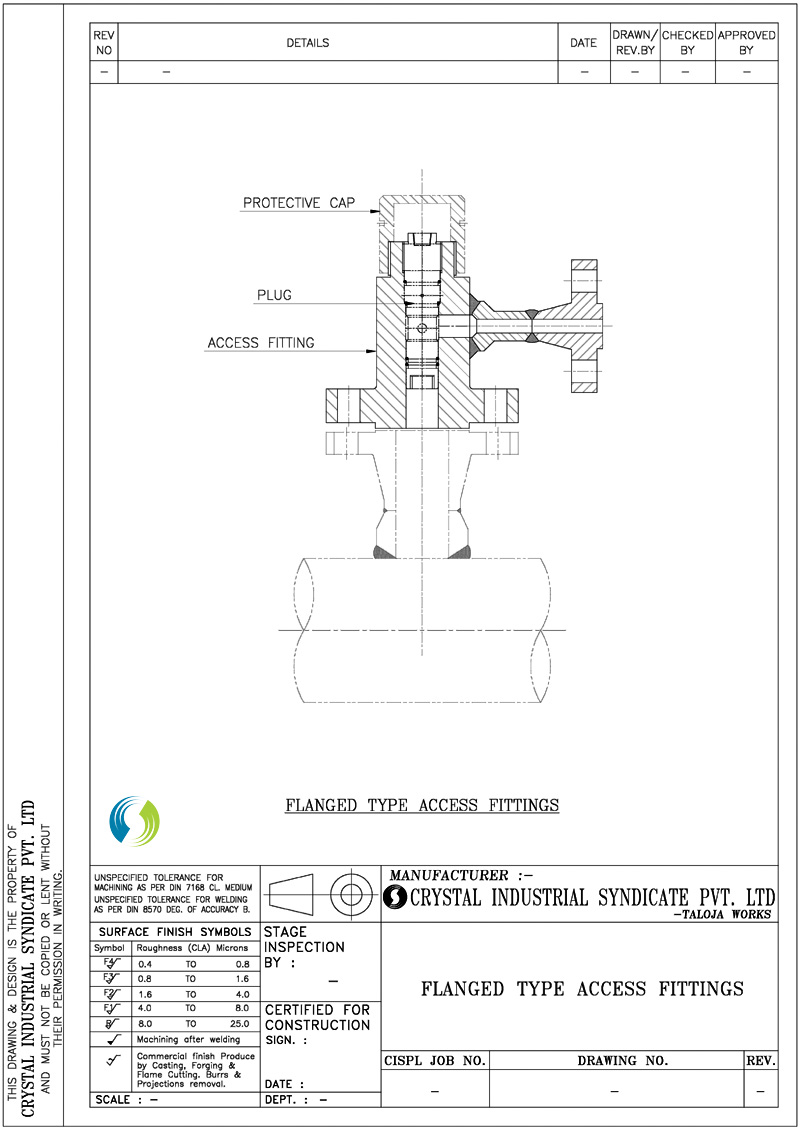

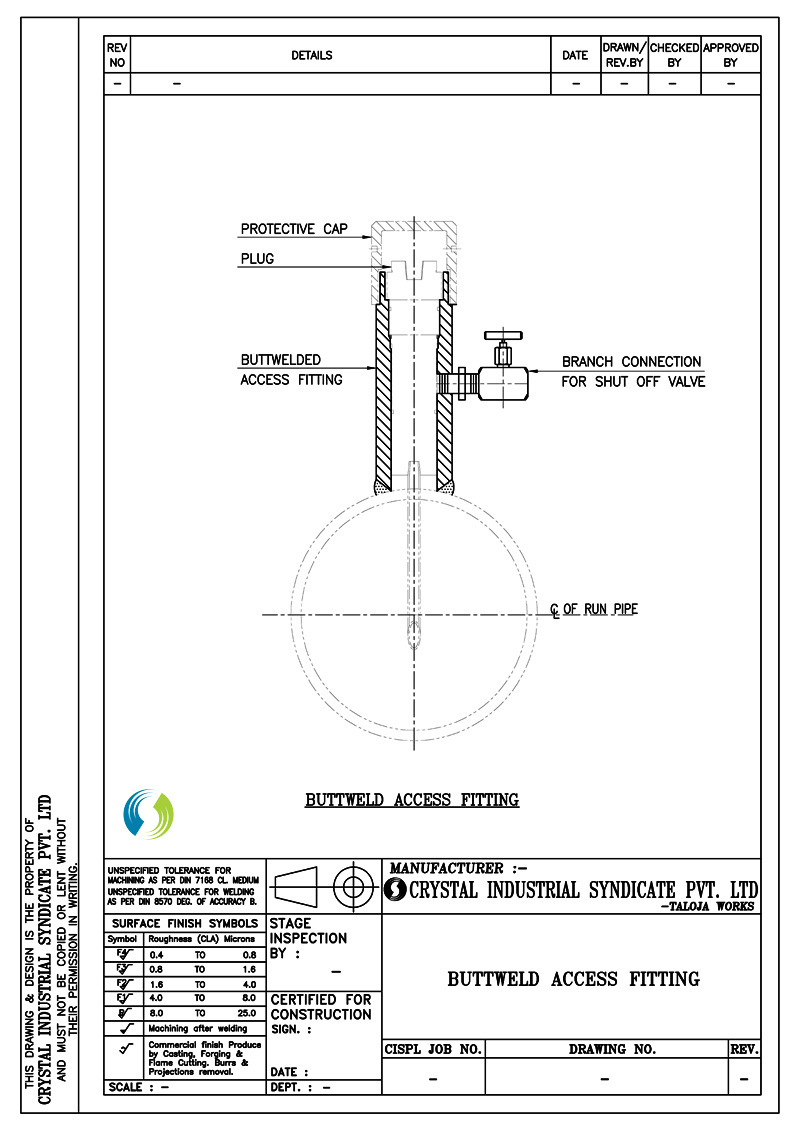

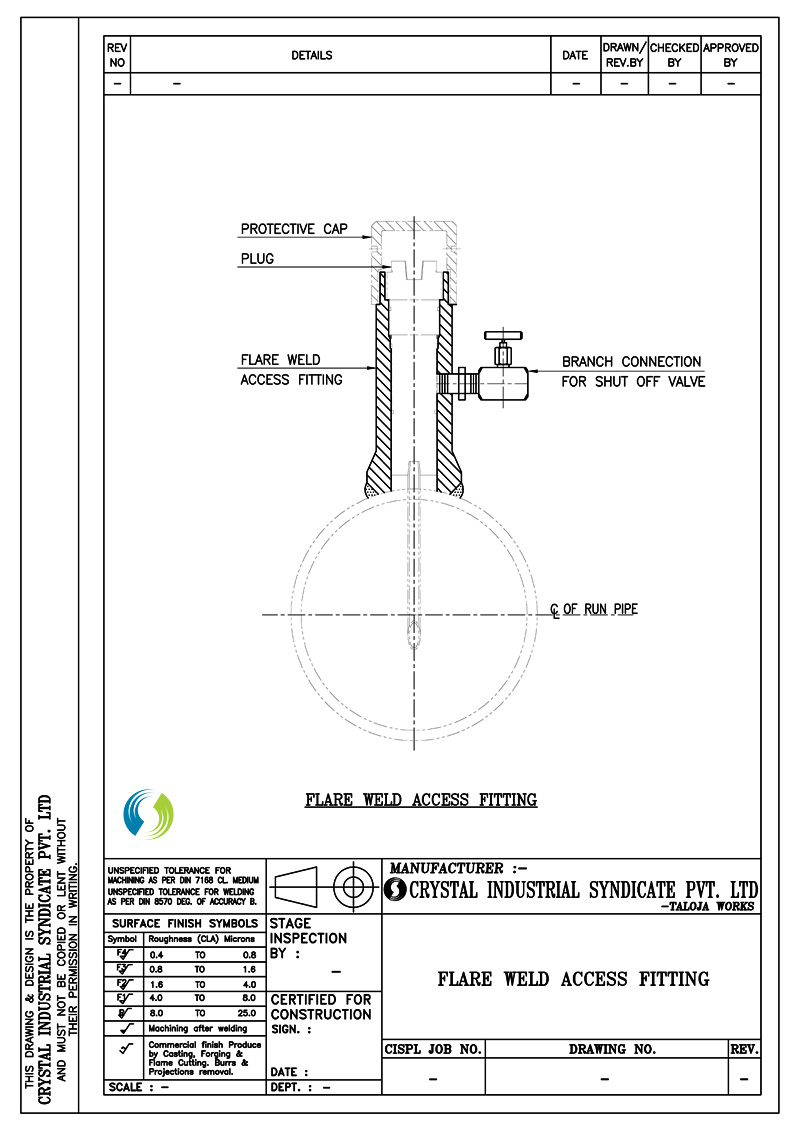

Access fitting body is permanently attached with the process plant vessel or pipework. It is a specialized pipe fitting. Access fitting bodies can also be flange mounted or welded.

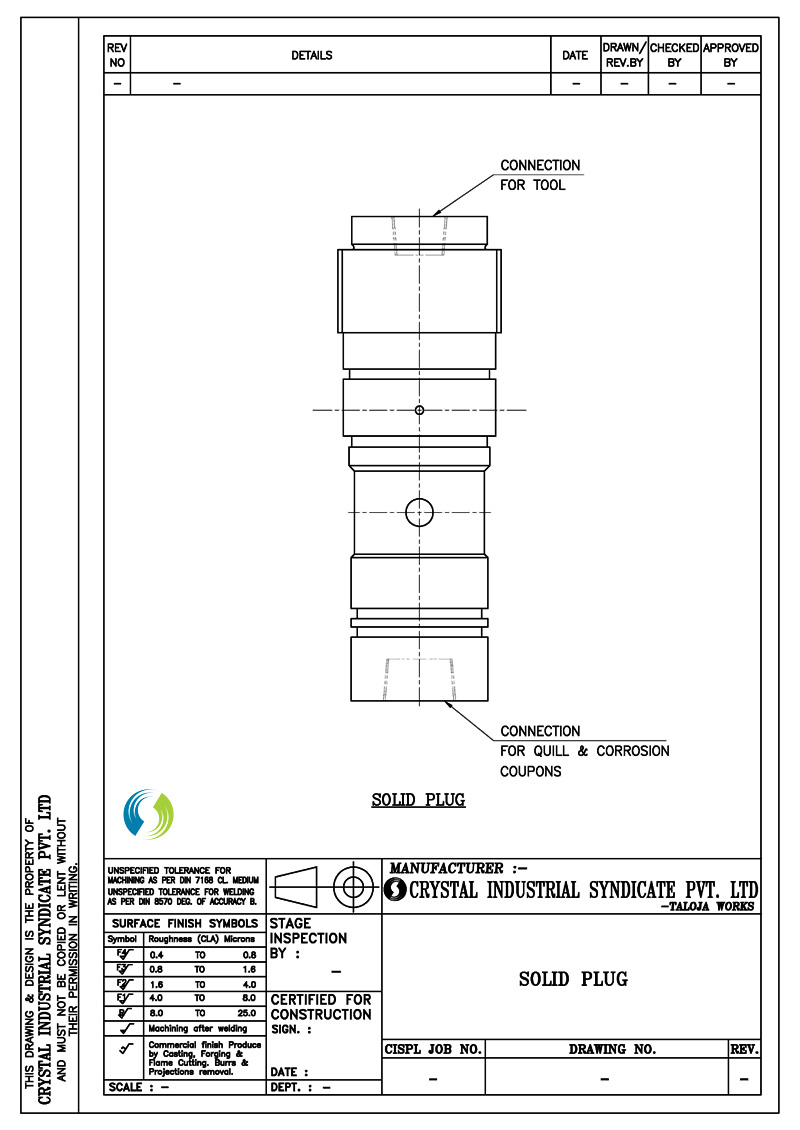

For the installed device, the Plug assembly is the carrier. Based on the type of device being used, a solid plug assembly or a hollow plug assembly is chosen. The plug assembly screws into the access fitting body and seals the fitting's bore to restrict line pressure.

Together with its plug assembly, the access fitting body and cover (designed to protect the external thread) is called access fitting assembly.

The retrieval tool and service valve are components needed to perform online installation and retrieval of the plug assembly. When the plug assembly is removed during the retrieval procedure, the service valve is used to restrict line pressure. Just one service valve and one retrieval tool can be used to maintain multiple access fitting assemblies.

A variety of devices have been designed for use with high pressure access fittings. Typically the following equipment can be installed into process lines using standard access fitting assemblies:

- Corrosion Coupons

- Linear Polarization Probes

- Thermowells

- Biological Probes

- Electrical Resistance Probes

- Hydrogen Probes

- Erosion Probes

- Sacrificial and Impressed Current Anodes

The following functions can be additionally undertaken with the use of access fitting bodies which incorporate a side-tee.

- Process Sampling

- Chemical Injection

- Sand Monitoring

Crystal Industrial offers two different styles of high pressure high pressure access fittings :

Generic design : This system is compatible and interchangeable with access fitting equipment produced by leading manufacturers.

Proprietary design : Incorporates various unique features which are an improvement on the generic design.