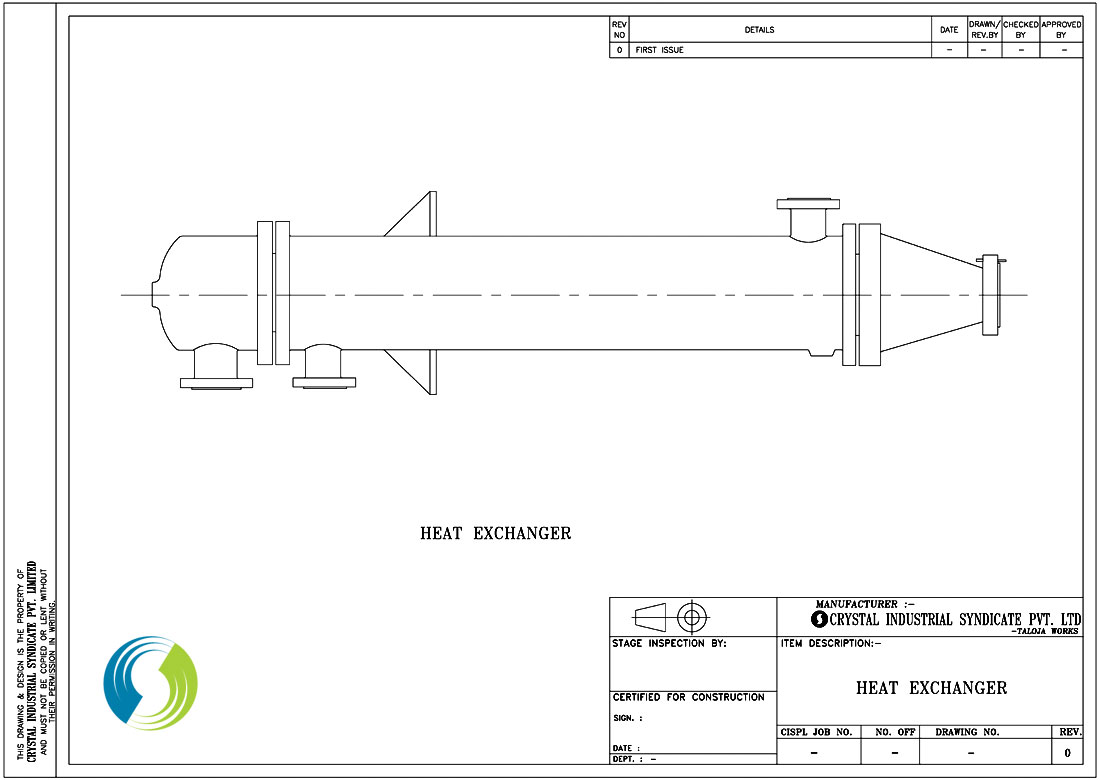

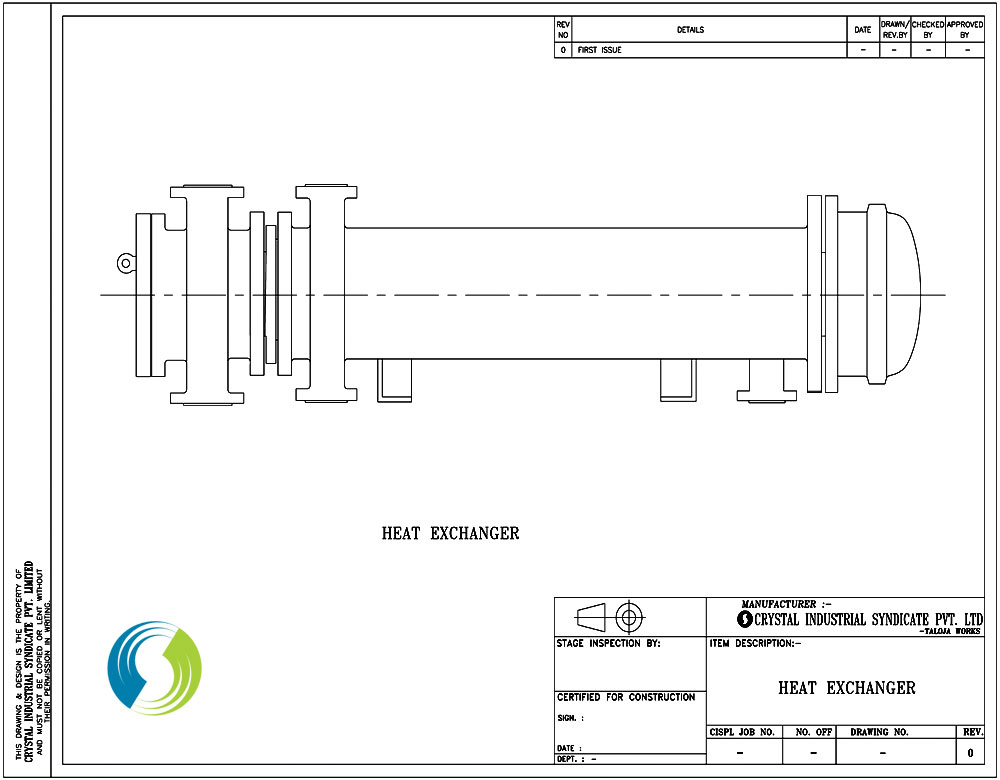

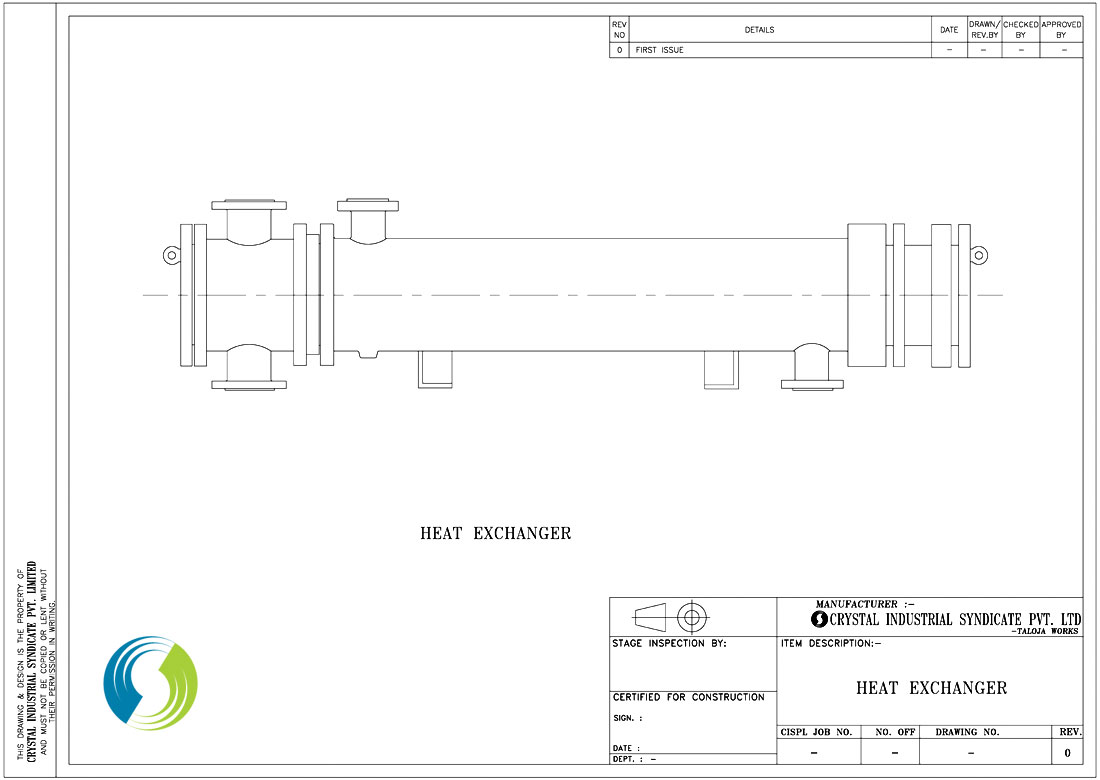

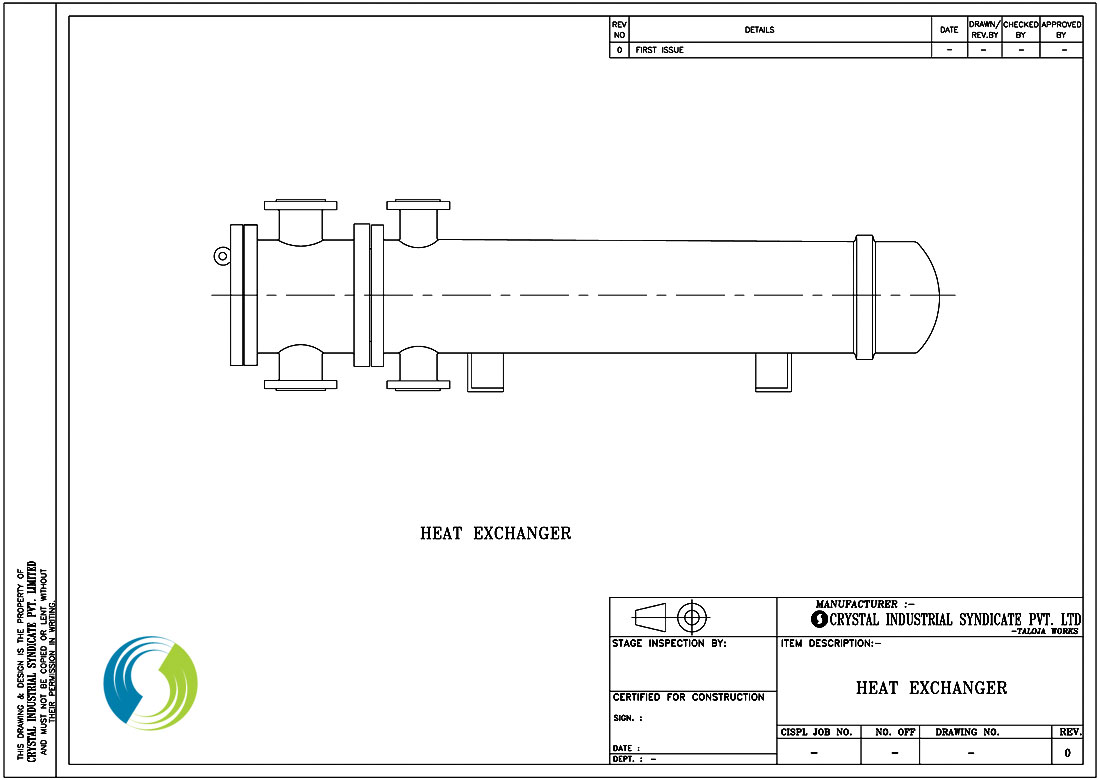

Heat Exchangers

For crystal, Shell and Tube Heat Exchanger manufacturing is a natural extension of its exotic materials fabrication expertise. Today's process industry demands more and more equipment in exotic material like Duplex Stainless Steel, Monel, inconnel, Titanium, Clad Materials etc.

Crystal Harnesses its expertise in manufacture of these materials and welding of dissimilar materials to deliver high quality "shell and Tube Heat Exchanger"". All Products From Crystal come with same quality of highest Standard, Which has earned them the authorization to use certification stamp.

Applications

Shell and tube heat exchangers are widely used in various applications Oil & Gas, Refineries, and other large chemical processes and is suited for higher pressure industrial process applications. They are available in various Diameters and lengths. The heat exchangers are designed for a wide range of liquid to liquid and steam to liquid application.

The shell and tube heat exchangers are constructed using tube sheet tube baffles and shell. it is manufactured using the most advance technology available and is specifically engineered for a wide range of applications. Every unit is designed, manufactured and tested to meet the quality requirements of ASME codes.