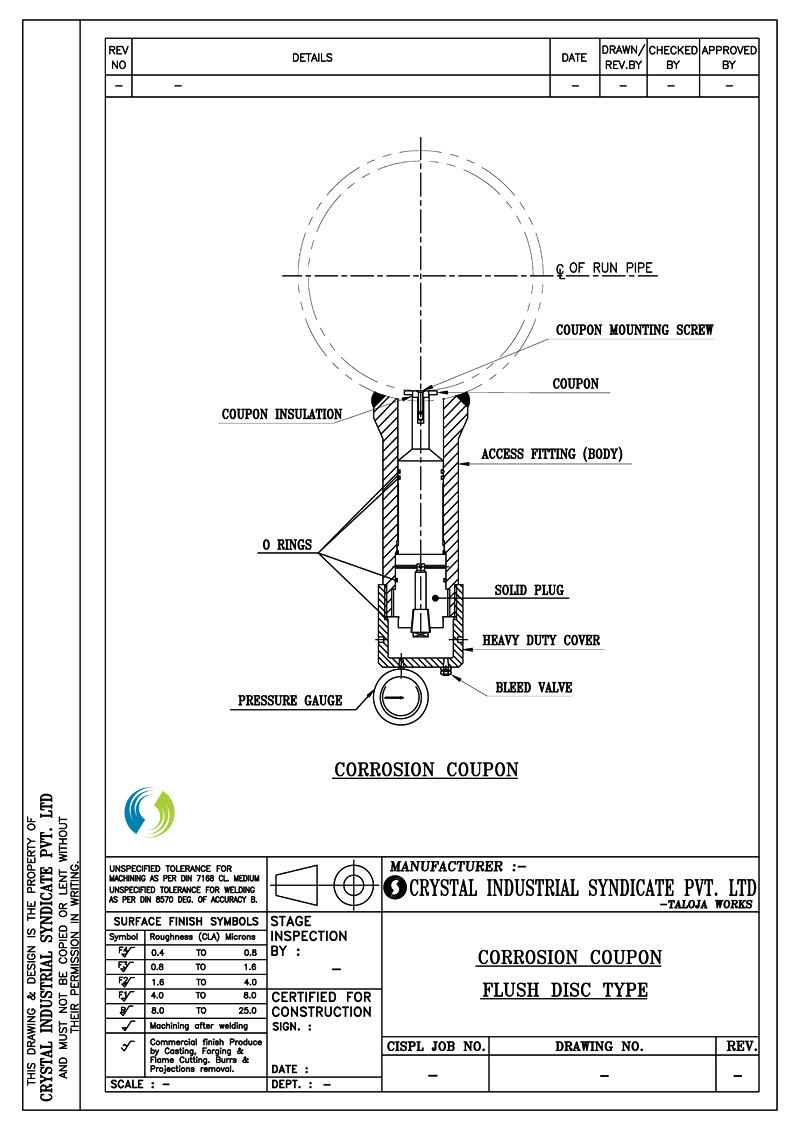

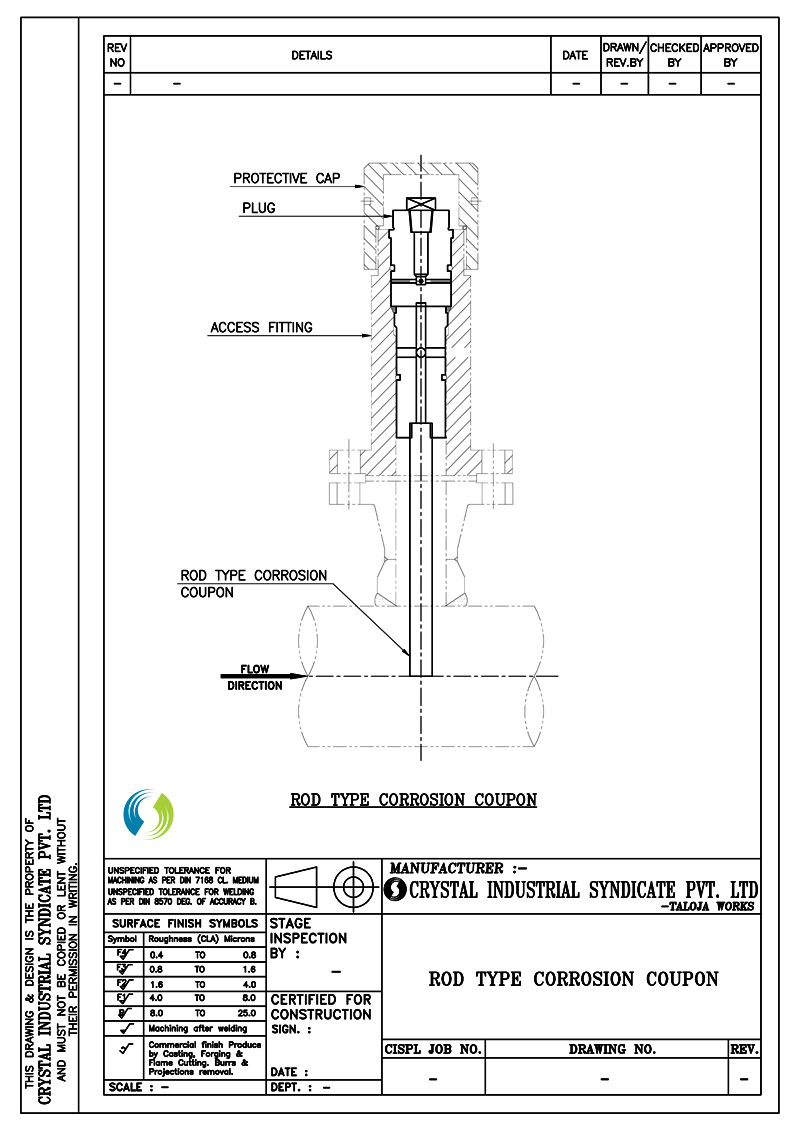

What Are Corrosion Coupons

Crystal's Corrosion coupons from India are an efficient tool for quantitatively estimating the corrosion rates occurring in an operating system. They also offer a visual indication of the type of corrosion that may be occurring in the system being monitored. Today, corrosion coupons are the simplest and most widely used method of measuring corrosion.

Crystal's Corrosion coupons from India are an efficient tool for quantitatively estimating the corrosion rates occurring in an operating system. They also offer a visual indication of the type of corrosion that may be occurring in the system being monitored.

What is a CORROSION COUPON?

- Is essentially a piece of metal of a predetermined size, shape and surface area

- Is a metal with chemical composition that's identical to that of the process equipment

- Provides a uniform reproducible surface finish

- Has a unique serial number

- Is exposed to the same corrosive medium as the process equipmen

- Is exposed to the corrosive medium for a fixed period of time

- Gives visual indication of the type of corrosion

- Indicates the rate of corrosion