High Energy Venturi Scrubber All Products

PRINCIPLES OF OPERATION

High Energy Venturi Scrubbers are designed for the removal of sub-micron fumes, mists, and particulates. The gas is accelerated into the throat of the venturi where the high velocity gas stream shatters the scrubbing liquid into fine droplets which mix with and impinge on the fine fumes, mists, and particulates to effect the required removal efficiency.

The scrubber are vertical flow, wet approach type where the scrubbing liquid is introduced at the top of the converging section of the venturi. The wet approach feature allows the scrubber to be used in hygroscopic or highly abrasive applications. These units are capable of scrubbing with recirculated slurries having a solids content as high as 30%.

The throat area of the venturi can be selected to operate at pressure drops between 6” (150 mm) and 120” (3000 mm) column of water.

TYPE 970

The Type 970 Scrubber is a fixed throat venturi available in smaller sizes for lower end of the capacity range.

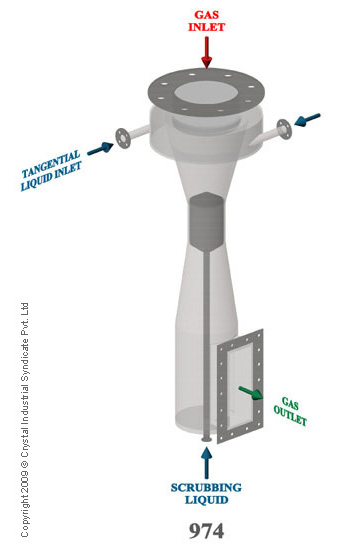

TYPE 974

The Type 974 Scrubber is an annular fixed throat venturi in which the throat is formed by the annular area between the outer body and a center body (plug). Scrubbing liquid is introduced at the center body as well as at the top of the converging section.

TYPE 975

The Type 975 Scrubber is the variable throat version of the Type 974 Annular Venturi Scrubber. The area of the annular venturi throat is varied by the vertical movement of the tapered center body (plug) in a conical throat body. The liquid may be introduced through the center pipe or by a top radial liquid inlet and the external wall tangential liquid inlets.

The scrubbers are vertical flow, wet approach type where the scrubbing liquid is introduced at the top of the converging section of the venturi. The wet approach feature allows the scrubber to be used in hygroscopic or highly abrasive application. These units are capable of scrubbing with recirculated slurries having a solids content as high as 30%.

The throat area of the venturi can be selected to operate at pressure drops between 6” (150 mm) and 120” (3000 mm) column of water.

In technical collaboration with Severn Trent Services