ECS Ejector Venturi All Products

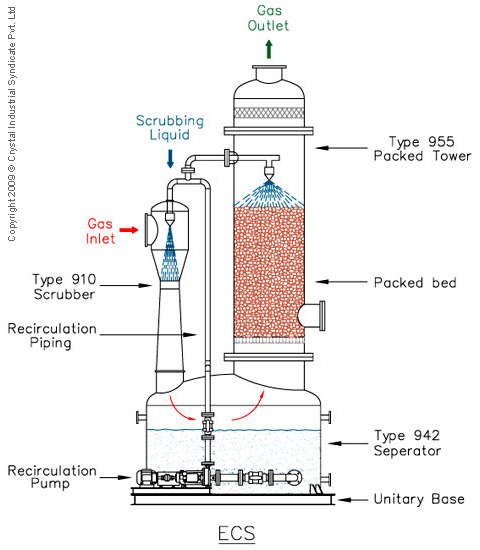

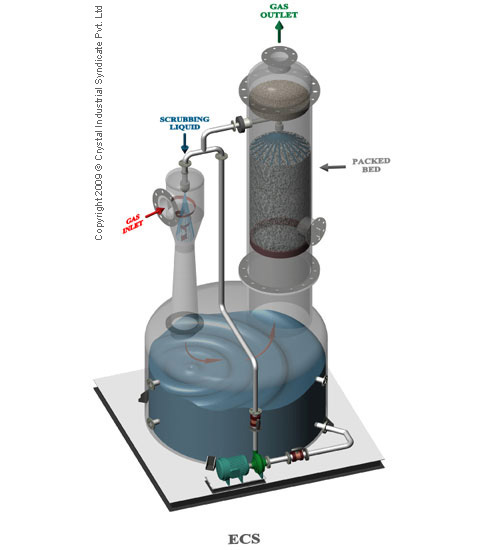

The ECS is a standard ejector–venturi, packed tower system which has been widely applied throughout industry for the absorption of various gases including chlorine. Fans are not required as the highly reliable ejector-venturi scrubber entrains the contaminated gas and causes air movement through the system. The first stage venturi is well suited to handle the high initial concentration of chlorine gas. After the gas exits the venturi the caustic is disengaged and contained within the separator. The gas then passes through the packed tower where the chlorine concentration is reduced to a level below, that required by the prevailing fire codes. A recirculation pump supplies the required caustic solution to the ejector-venturi scrubber and the packed lower.

The flow of liquid and gas is both co-current and counter-current with a liquid rate to each stage matched to absorption performance. This precludes the possibility of caustic starvation. The system has the capability to handle the worst case release rate of liquid chlorine based on total vaporization of chlorine.

The ECS 250 is designed to neutralize a 150 pound (70 kg) chlorine cylinder at a continuous leak rate of up to 20 pounds per minute (9 kg/min.; 540 kg/hr).

The ECS 3000 & 5000 are designed to neutralize a one ton portable tank with a leak rate up to 437 pounds per minute (200 kg/min.; 12,000 kg/hr) throughout the leak event. An ECS 5000 system is normally considered only when the gas capacity needs to be split between two or more rooms or if a single room volume exceeds 50,000 cubic feet (1,400 m3).

In technical collaboration with Severn Trent Services