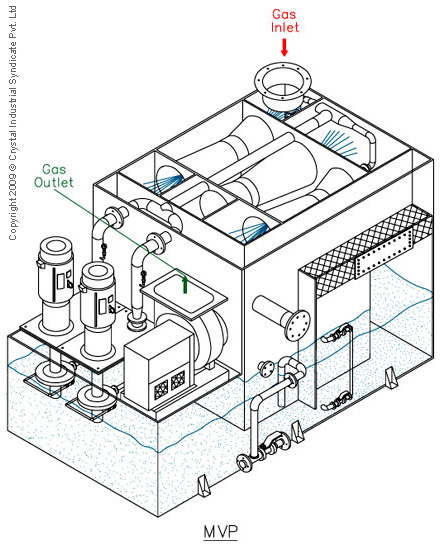

ECS Multi Venturi, Packless Fan-Driven All Products

At only 8 feet (2.5 m) tall, the fan-driven Multi Venturi Packless (MVP) scrubber is a low profile emergency chlorine scrubber. The fan-driven MVP system consist of six venturis in series with a downstream fan which keeps the entire scrubber system under a negative pressure. Even with fan failure, the venturis will provide a system capacity of about ⅔ of the rated capacity, or 2,000 cubic feet per minute (CFM) (3,400 m3/hr) for a 3,000 CFM (5,100 m3/hr) system.

The MVP is a low total horsepower system with a low liquid caustic pressure. Liquid and gas flow are co-current with a liquid rate of each stage matched to absorption performance, so there is no possibility of caustic starvation.

The caustic solution is supplied to each of the six venturi stages by a vertical seal-less recirculation pump. The system is available with either one or two pumps.

Advantage of the system include the lowest profile system available with the capability to handle the worst case release rate of liquid chlorine based of total vaporization of the chlorine. The chlorine concentration at the exit of the system is reduced to a level below that required by the prevailing fire codes. since there is no packing in the system, less surface area available for carbonate buildup during down periods. There fore, a longer caustic solution services life is expected.

The MVP 3000 and 5000 are designed to neutralize a one ton chlorine portables tank at a leak rate up to 437 pounds per minute (200 kg/min.; 12,000 kg/hr) throughout the leak event

In technical collaboration with Severn Trent Services