Packed Tower Scrubber All Products

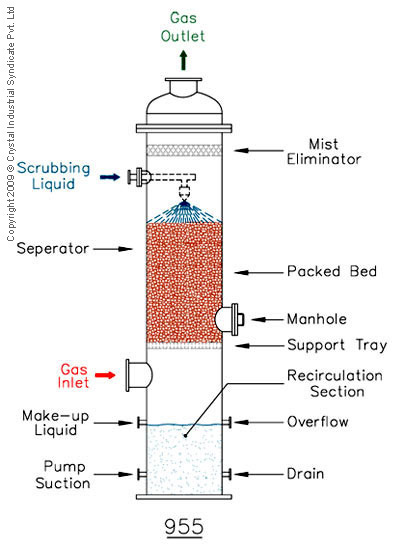

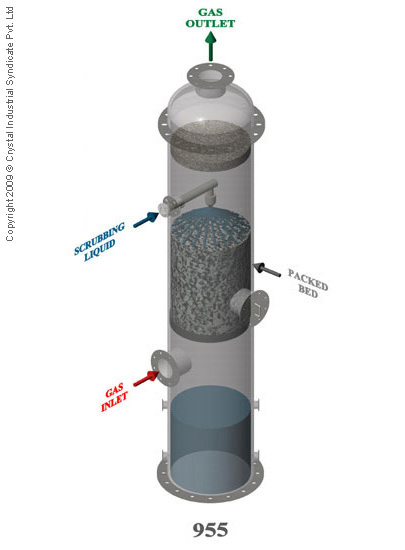

Type 955 Packed Tower Scrubber is a low energy, contact bed type of wet scrubber for gas absorption, for gas cooling, and for stripping of the contaminants, from process liquids. The units are specifically engineered to give the highest efficiency with the lowest power consumption without sacrificing performance reliability. Packed Tower Scrubbers are available in standard designs from 6” (150 mm) to 144” (3600 mm) diameter and with capacities to 50,000 cubic feet per minute (CFM) (85,000 m3/hr).

PRINCIPLES OF OPERATION

Contaminated gas enters bottom side of the scrubber and flows upward through the packed bed. The scrubbing liquid is introduced through a distributor at the top of the packed section and trickles downward through the packing, removing the contaminants from the gas through the interaction of the gas, liquid, and packing media. The scrubbing liquid falls to the recirculation sump at the bottom of the unit. The cleaned gas proceeds upward through a mist eliminator to the gas outlet.

PACKED BED

The types, size, and depth of packing is selected to provide the optimum in scrubbing performance.

SUPPORT TRAY

The packing support tray may be the gas injection type, having the lowest pressure drop with the most efficient gas distribution characteristics.

LIQUID DISTRIBUTOR

The scrubbing liquid is uniformly distributed to the packed bed by :

1) a single spray nozzle, or 2) multiple spray nozzles, or 3) wire type distributor, or 4) tray type distributor.

MIST ELIMINATOR

Liquid droplet carry over is prevented by a : 1) mesh pad media, or 2) loose packed bed, or 3) vane type mist eliminator.

RECIRCULATION SUMP

An integral sump is provided for the recirculation of the scrubbing liquid in order to lessen water consumption. The recycle section is provided with pump, drain, overflow, and make-up liquid nozzles.

TOWER SHELL

The unit has a bottom-side radial gas inlet, top central gas outlet, bottom integral recirculation section, and a top liquid inlet. The units are available in FRP; stainless and alloy steels; lined carbon steel; and FRP reinforced liners of PVC, CPVC; Halar, Tefzel, and FEP Teflon.

In technical collaboration with Severn Trent Services

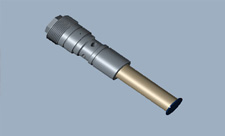

High pressure access fittings

High pressure access fittings

Fixed & Retractable Injection Quills

Fixed & Retractable Injection Quills

Corrosion coupons

Corrosion coupons

Required accessories

Required accessories